Autor: Marcin Żołnierczuk

SimDes engineers have extensive experience in most fields of CAE / FEA analysis of car interiors. We are engineering Instrument Panels and Centre Consoles for OEM’s and Tier 1 suppliers. By leveraging best FEA tools and methods we engineer weight and strength optimised parts which are meeting demanding structural, NVH and safety requirements.

Using CAE digital models of compleet Instrument Panels we test them comprehensively by applying normal, misuse, abuse and dynamic loads. We optimise cockpit structure to meet the critical safety regulation for FMVSS (Federal Motor Vehicle Safety Standards) and ECE (European) requirements.

We conduct FEA analysis according to:

- ECE Regulation 21 Interior Fittings–Head Impact Assessment

- FMVSS 201 Occupant Protection in Interior Impact – Upper Interior Head Impact & Lower Interior Head Impact

We optimise stiffness of parts directly subjected to occupant loads to assure expected firmness of feel and avoid flimsy experience and lack of durability.

We also predict cockpit squeak and rattle risk by using quick and reliable CAE tools.

Squeak and rattle is an issue for electric vehicles

Durability Analysis,

cockpit parts subjected to cyclic loading like gear shifter brackets, steering wheels, grab rails or armrest are virtually tested and design to meet customer durability expectations without extensive physical testing.

We conduct low and high-cycle fatigue assessment of metal and thermoplastic components to give design directions and finally release high quality components.

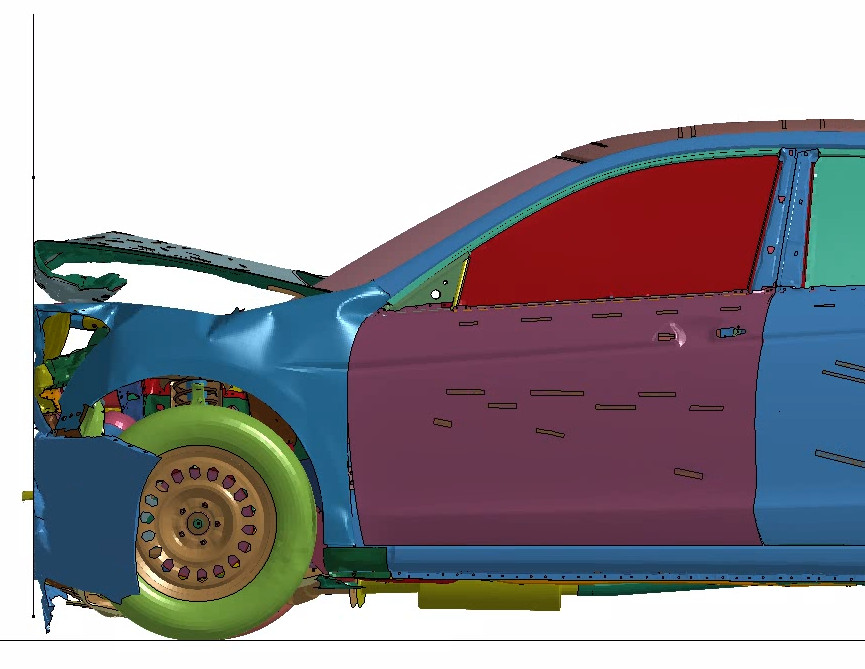

Structural Integrity Analysis,

of cross car beams during crash event is also within our scope of experience, the major load paths must be retain during crash, failure of mounting points of steering column is not permitted.

Structural integrity during crash - Cross Car Beam Engineering

Results from FEA simulation of cross car beam during dynamic event allows optimise geometry to meet legal requirements and deliver lightweight component.

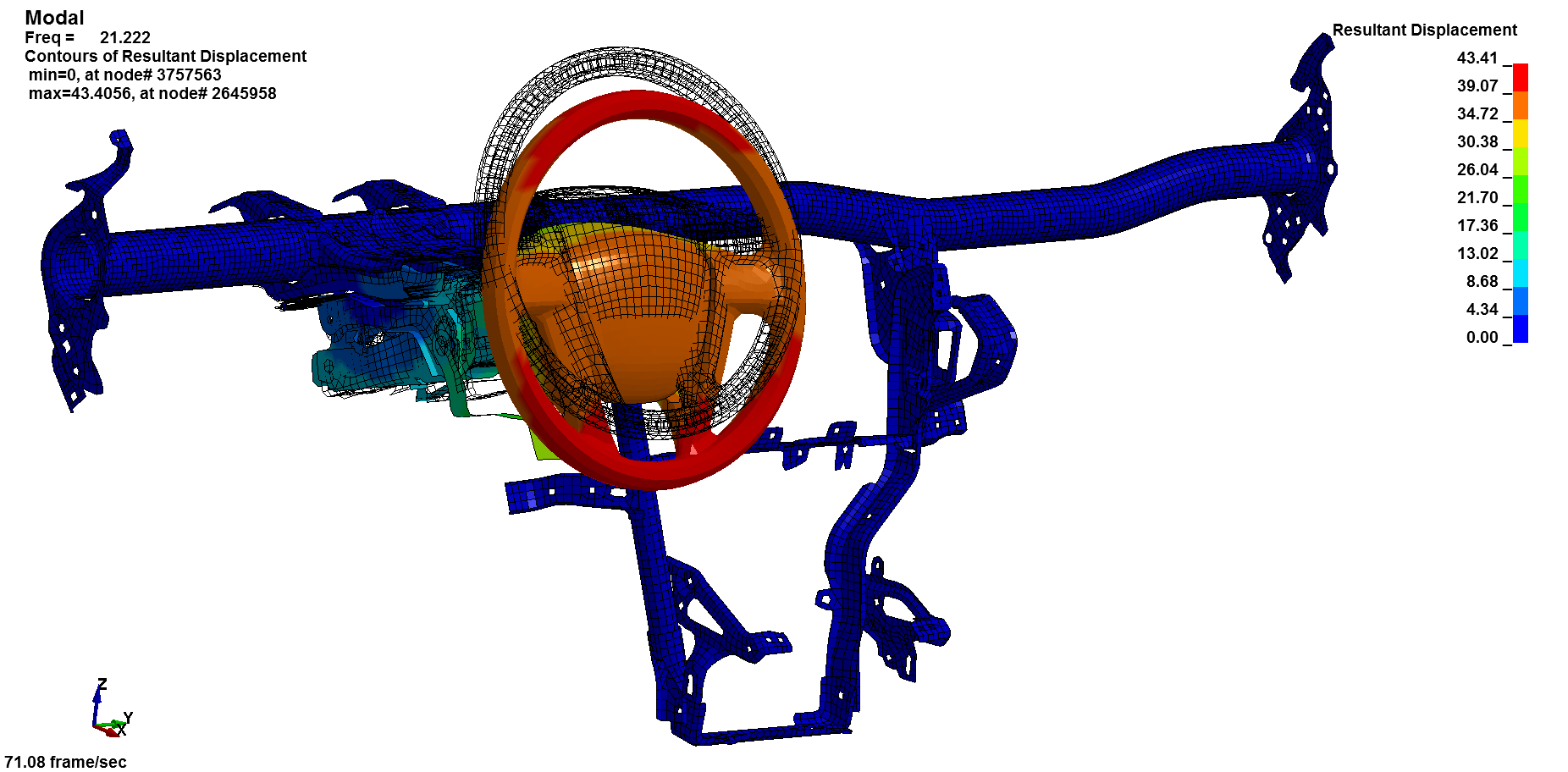

Vibrarion (NVH) Analysis,

FE vibration analysis allows the prediction at the early design stage of potential issues with high vibration caused by a resonance frequency or high harmonic excitation (road and engine excitation).

Modal analysis of steering wheel vibration and cross car beam

Dynami stiffness of cross car beam is crucial for driver comfort when holding steering wheel for few hours, even minor vibration can reduce the product quality.

Contact us if you would like to discuss how we can help you deliver great product

Connect With Us On Social Media

SimDes Partner

phone:

+48 514 514 243

email:

address:

ul. Żurawia 6/12 lok. 766

00-503 Warszawa

Poland

Quick contact